Comprehensive Guide to Microcement Application

Microcement Application: Detailed Guide and Process

Microcement is a versatile and innovative material used in modern construction and interior design. Its application in bathrooms and wet rooms has gained popularity due to its durability and seamless finish. In this article, we will explore the history of microcement, the different types of colors available, the time frame for its application, and the step-by-step process involved in applying microcement, with a focus on bathrooms and wet rooms.

History of Microcement

Microcement, also known as micro concrete or micro screed, originated in the early 2000s as a solution for creating seamless and continuous surfaces. It is a cement-based coating that can be applied to various surfaces, including floors, walls, and furniture. Over the years, its use has expanded due to its aesthetic appeal and practical benefits.

Types of Colors

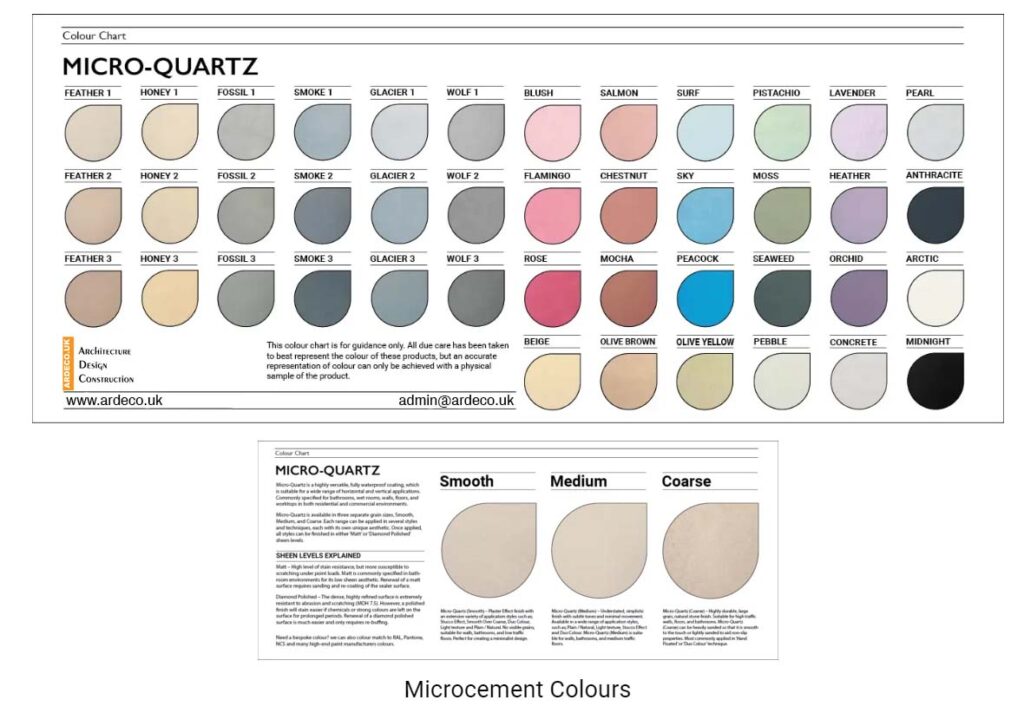

Microcement is available in a wide range of colors, allowing for customization to suit any design aesthetic. The most common colors include shades of grey, white, and beige, which provide a modern and minimalist look. However, it is also available in more vibrant colors like blue, green, and red for more daring designs. The color is added during the mixing process, ensuring a consistent hue throughout the application.

Time Frame from Application to Use

The application of microcement is a multi-step process that typically takes around 5 to 7 days to complete. This time frame can vary depending on the size of the area and the complexity of the design. Here is a breakdown of the timeline:

- Preparation: 1-2 day

- First Layer Application: 2-3 day

- Sanding and Second Layer Application: 2-3 days

- Final Sanding and Sealing: 2-4days

- Curing Time: 1-2 day

Initial Preparation for Microcement

The first step in applying microcement is to prepare the surface. This involves cleaning the area thoroughly to remove any dirt, grease, or debris. Any cracks or holes should be filled, and the surface should be sanded to create a smooth and even base. A primer is then applied to ensure good adhesion of the microcement.

First Layer Application

Once the surface is prepared, the first layer of microcement is applied. This layer serves as the base coat and is usually around 1-2 mm thick. It is applied using a trowel in thin, even coats. This layer needs to dry for at least 24 hours before the next step.

Sanding and Second Layer Application

After the first layer has dried, it is lightly sanded to remove any imperfections. The second layer of microcement is then applied in the same manner as the first. This layer is also around 1-2 mm thick and needs to dry for another 24 hours.

Final Sanding and Sealing

Once the second layer is dry, it is sanded again to achieve a smooth finish. The surface is then cleaned to remove any dust. A sealer is applied to protect the microcement and enhance its durability. The sealer also provides a water-resistant barrier, making it ideal for bathrooms and wet rooms. The sealed surface needs to cure for 24 hours before it can be used.

Specialized Application in Bathrooms and Wet Rooms

Applying microcement in bathrooms and wet rooms requires special attention to detail. The seamless and water-resistant properties of microcement make it an excellent choice for these areas. However, it is crucial to ensure proper sealing to prevent water penetration and damage.

In bathrooms and wet rooms, the microcement is applied to all surfaces, including floors, walls, and even shower enclosures. This creates a cohesive and modern look. The application process is similar to that of other areas but with additional steps to ensure waterproofing. A waterproof membrane is often applied before the microcement to provide an extra layer of protection.

Benefits of Using Microcement in Bathrooms and Wet Rooms

Microcement offers several benefits when used in bathrooms and wet rooms:

- Seamless Finish: Eliminates grout lines, reducing areas where mold and mildew can develop.

- Durability: Highly resistant to wear, scratches, and impacts.

- Water Resistance: When properly sealed, provides excellent protection against water penetration.

- Versatility: Can be applied to various surfaces, including tiles, concrete, and plasterboard.

- Low Maintenance: Easy to clean and maintain, requiring only regular wiping with a damp cloth.

Conclusion

Microcement is a versatile and durable material that offers a seamless and modern finish, making it an ideal choice for bathrooms and wet rooms. By following the proper application steps, from initial preparation to final sealing, you can achieve a beautiful and long-lasting result. With its wide range of colors and design possibilities, microcement allows you to create a unique and stylish space tailored to your preferences.

If you’re interested in mold removal and remediation services, feel free to contact us:

- Website: www.ardeco.uk

- Email: admin@ardeco.uk

- Phone: +44 7393 115904